With the surge of EVs, battery trays have become indispensable. They do much more than just hold battery packs: they provide crucial mechanical protection, ensure structural stability, and manage thermal conditions. Ensuring these trays remain leak-free is critical, as even tiny leaks can lead to damaging short circuits or potential fires. Helium leak testing has emerged as a dependable solution, thanks to helium's unique properties. As interest in EVs continues to grow, maintaining strict safety standards to ensure the leak-tightness of battery trays is becoming increasingly crucial. How does all this work in the electric vehicle and automotive market? We aim to address this question in our blog post.

Industry context and the criticality of leak prevention

In the case of electric vehicles, the battery tray, often referred to as the car battery tray or battery box, plays a pivotal role. It's not just a mere battery holder but a critical component that integrates seamlessly with the vehicle's energy system. These trays offer essential mechanical protection and structural stability, safeguarding the battery pack in various environments and conditions. Similarly, we can take the boat battery tray in the marine world as an example, providing a robust shelter against outside influences. Moreover, they actively contribute to cooling and thermal management, which are vital for maintaining optimal battery performance.

However, if these trays have even the slightest leakage, they can cause significant problems. Water or moisture finding its way into an electric vehicle battery tray can lead to severe damage. This intrusion may trigger short circuits or even fire hazards, undermining the vehicle's safety. Over time, these leaks can cause the degradation of battery performance, drastically shortening its lifespan. Additionally, the presence of moisture or contaminants raises the risk of corrosion, which can compromise the entire battery management system.

Due to the potential dangers associated with leaks, stringent regulatory and safety standards dictate that battery trays must achieve 100% leak-tightness. These regulations ensure that every electric vehicle operates reliably and safely, emphasising the need for rigorous testing and quality assurance throughout the production process. Maintaining this high standard is crucial, not just for compliance but for the safety and trust of everyone who relies on the technology.

Helium as the ideal leak testing medium

In the aspect of battery trays, ensuring safety and rigidity is fundamental. One effective leak testing method that stands out is helium leak testing. Renowned for its unique properties, helium is an inert gas, meaning it won't react with other substances. It's also non-toxic, making it safe for both the environment and the workers handling it.

Thanks to its small molecular size, helium is exceptionally adept at finding its way through even the tiniest of leaks. This makes it ideal for detecting micro-leaks that could potentially compromise the integrity and safety of battery trays over time. When it comes to reliability, helium-based testing is unmatched. It offers high sensitivity, ensuring each test is precise and trustworthy. This is particularly important for battery trays, which often have complex geometries that require meticulous evaluation.

Moreover, helium is a lightweight gas, meaning its particles can permeate materials quickly, ensuring a rapid and thorough inspection. For those seeking a method that combines efficiency and thoroughness, helium leak testing proves to be an exceptional choice.

Validated testing methods for battery trays

Ensuring the integrity of battery trays in EVs is no small task. Various testing techniques have been established to verify their leak-tightness, and each method has its unique application.

Firstly, there's accumulation testing, which is particularly effective for larger systems operating under low pressure. This method involves sealing the entire system in a chamber and measuring any changes in helium concentration (or measuring the amount of escaping helium molecules). It's like setting a trap for any escaping gas, and it's incredibly effective at catching even the smallest breaches over time.

Next, we have sniffing detection. This method allows for manual inspection, making it ideal for locating specific leak sites. Often employed during maintenance or final validation checks, sniffing ensures that nothing slips through the cracks in quality control.

Finally, there's the hard vacuum testing method. This technique is the gold standard for sensitivity. By using a mass spectrometer within a vacuum chamber, even the tiniest leaks are detectable. This approach is particularly suited for manufacturing environments that set high demands on quality and accuracy.

Each of these testing methods plays a crucial role in safeguarding the performance and safety of EV battery trays. Utilising them appropriately ensures these vital components remain as secure and reliable as possible.

MVS Technologies' solutions

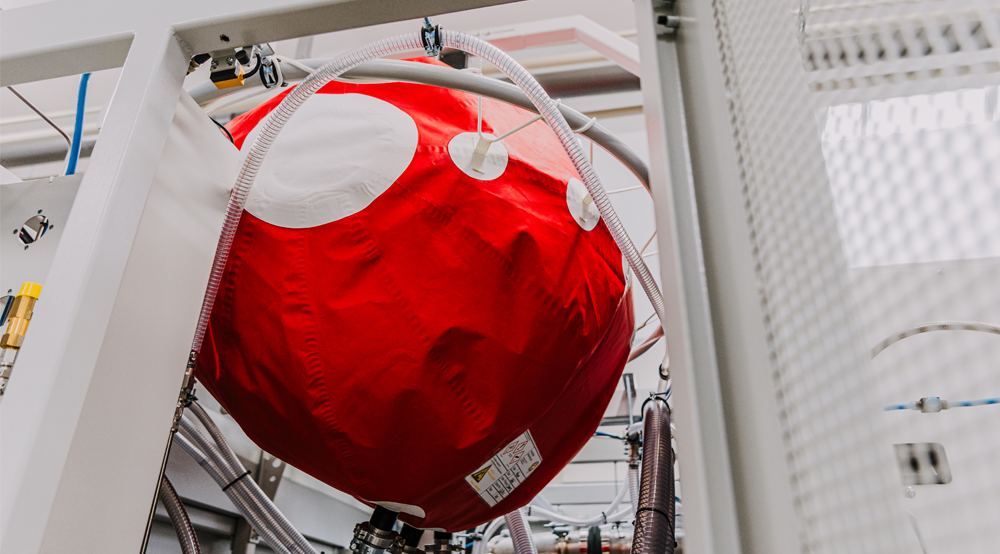

When it comes to ensuring the leak-tightness of battery trays in electric vehicles, MVS Technologies offers cutting-edge solutions tailored to meet the industry's high demands. Our systems, whether fully or semi-automated, are expertly designed to test the integrity of EV battery trays. With MVS Technologies, you're equipped with the ability to perform all three primary testing methods—accumulation testing, sniffing, and hard vacuum testing—efficiently and accurately.

Furthermore, these systems offer the option of integrated or standalone Helium Recovery Units (HRUs). This not only ensures thorough testing but also adheres to sustainable practices by recovering and recycling heliumduring the testing process.

The importance of helium leak testing in EV battery trays cannot be overstated. It plays a key role in maintaining the safety and reliability of electric vehicles, preventing costly or dangerous failures. MVS Technologies stands out as a leader, providing comprehensive and innovative solutions that address the unique challenges associated with battery tray testing. Our advanced systems ensure that EV manufacturers can meet stringent safety standards while embracing sustainable practices. This makes us an invaluable partner in the journey toward safer and more efficient electric vehicles.