The most common helium leak detection methods

Helium leak detection stands as a pivotal process across multiple industries, anchoring itself as a method of choice due to its reliability and precision. This advanced technique is utilised widely from the automotive to aerospace industries, and electronic manufacturing to pharmaceuticals, underpinning the safety, efficiency, and integrity of products and infrastructure. In this blogpost 8 effective methods will be introduced, which are essential to reach the quality standards.

Helium leak detection is a guardian of quality and safety in a vast array of applications. By leveraging the unique properties of helium—its rarity in the atmosphere, non-reactive nature, and the ability to swiftly move through tiny leaks—it becomes an obvious choice for identifying even the most elusive of leakages.

As industries continue to expand the boundaries of innovation and safety, the role of helium leak detection only becomes more crucial. Its ability to deliver precise diagnoses without introducing contaminants makes it an indispensable tool in the modern technological landscape.

Why Helium is ideal for leak detection?

Helium, a noble gas known for its rarity and unique characteristics, stands out as an exceptional choice for leak detection in a multitude of industrial applications. Its notably low abundance in the atmosphere—approximately 5 parts per million—makes it an excellent candidate for identifying leaks without the background noise typically associated with more prevalent gases. This near absence ensures that even the smallest of leaks can be detected with high precision.

The inert and non-reactive nature of helium is another benefit that cannot be overstated. Unlike many other gases, helium does not react with other elements or compounds. This means it can safely be used in various environments without concern for chemical interactions that could compromise the integrity of the testing process or the materials involved.

Moreover, helium is incredibly light and mobile. Its small atomic size allows it to swiftly navigate through even the smallest openings, making it ideal for thoroughly testing sealed environments for any breach in containment.

In practical applications, helium leak detection offers substantial benefits over other tracers. It is non-toxic and non-flammable, additionally, the speed with which helium can fill a space and subsequently be measured is unmatched, facilitating faster and more efficient testing cycles.

Industry-standard practices have cemented the role of helium in leak detection, endorsed by global safety and quality standards. Its usage spans critical sectors including aerospace, automotive, and electronics, where ensuring absolute containment is not just a regulatory requirement but a necessity to safeguard functionality and durability.

Let's see, what are the most common helium leak detection methods!

The eight methods of helium leak detection

As we delve into the eight primary methods employed, we uncover how each technique serves unique roles and fits specific scenarios.

- Spray method

The spray method revolves around the application of helium to the outer surfaces of a sealed apparatus under test conditions. By carefully spraying helium while monitoring the interior for its presence, technicians can pinpoint leak locations with high accuracy. This technique shines when utilized in finding singular, small leaks on relatively simple test setups. - Vacuum hood method

Transitioning to the vacuum hood method, this approach involves placing a dome or hood over the test object, evacuating the air, and then introducing helium. It is adept at quantifying the total leakage of systems that can be fully or partially enclosed. Industries that handle sensitive components often rely on this method when precision is non-negotiable. - Sniffer method

The sniffer method is an excellent alternative where components cannot be enclosed, or to find the exact location of the leak, or to find the reason (rout cause) of the leak’s origin. Using a handheld probe, operators detect helium emissions from pressurized parts. This method is particularly effective for example in complex geometries, providing a flexible solution to challenging environments. - Pressure accumulation method

Enhancing detection sensitivity, the pressure accumulation method builds upon the sniffer technique by enclosing the test object and allowing helium to accumulate over time. Mostly suited for smaller leaks, this method offers a balance of sensitivity and application in environments that require high accuracy. - Suction cup method

Designed for large objects or areas that cannot be tested in their entirety, the suction cup method focuses on localized areas using a partial vacuum to detect leaks. This approach is crucial for huge vessels or tanks where might be pressure during operation inside the vessel and using the cup from the outside. - Bell jar method

Next, the bell jar method introduces a high-sensitivity scenario. By placing the object in a controlled chamber and subjecting it to helium under vacuum, it achieves a high level of accuracy, especially compared to other pressure methods. This method is the go-to when finding leaks in highly sensitive or critical equipment. - Bombing method

The bombing method involves enveloping the test object in a helium atmosphere under pressure to force helium into potential leaks, later detected in a vacuum chamber. This method is extensively used for testing sealed components like electronic packaging or medical devices to ensure absolute integrity. - Arbitrary pressure method

Finally, the arbitrary pressure method, customized for varying pressure requirements, allows for adjustable testing parameters. Its flexibility makes it suitable for low-pressure applications and diverse product tests, proving essential in industries requiring adaptable and rigorous testing standards.

By understanding and applying these eight methods of helium leak detection, industries can embrace a proactive approach to maintaining system integrity and safety. Each method, like a specialized tool in a toolbox, has its niche, ensuring that no leak, however elusive, remains undetected.

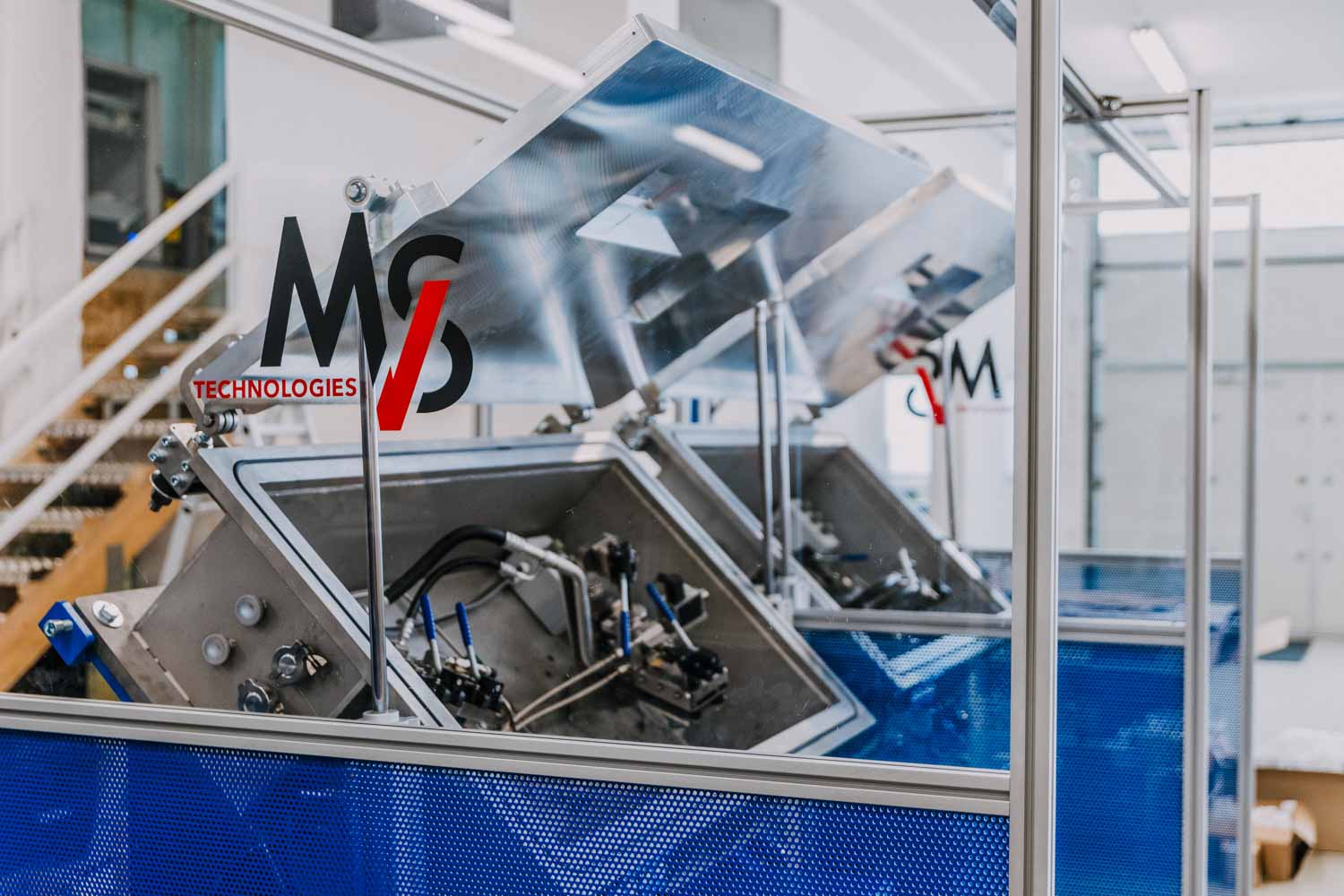

In an era where the minutiae of technical precision can dictate the success or failure of entire industries, MVS Technologies continues to innovate and lead. Their dedication to improving helium leak detection technologies speaks to their role as a key player in safeguarding the integrity and reliability of numerous high-stakes operations worldwide.