Leak testing solutions: A Guide to achieving optimal quality and safety

Leak testing stands as a cornerstone in the realm of quality assurance, bringing together technology, precision, and manufacturing to ensure that products not only meet but surpass performance and safety expectations. This process is integral to sectors where the integrity of each component can decide the line between optimum functionality and potential failure. Leak testing is much more than a mere procedure, it's a requirement in today's industrial landscape, characterized by rapid technological evolution and growing consumer demands for safer, longer-lasting products. Let's discover the most effective leak testing solutions!

The technology wrapped around leak detection equipment has transformed significantly, offering a plethora of options to catch even the minutest imperfections that could compromise a product's performance. These advancements in leak detection not only streamline production lines but also enhance safety protocols, ensuring that all manufactured goods adhere strictly to global standards.

The methods employed, ranging from simple visual inspections to sophisticated equipment-based tests, are pivotal in maintaining quality control across various industries. Implementing effective leak testing solutions not only boosts product reliability but also shields companies against the economic repercussions of recalls and reputational damage.

The objective of leak testing

At its core, the objective of utilizing diverse leak testing methods is to discern and deter potential flaws that could undermine the intended operation of a product. Whether it’s a microscopic fissure in a medical instrument or a tiny seam in automotive components, identifying such defects early in the production cycle is crucial. This proactive approach not only fulfills the fundamental requirement of delivering defect-free products but also instills a sense of reliability and trustworthiness in the brand.

Furthermore, adhering to stringent leak detection standards is not just about meeting production norms but is a critical component of ensuring safety. From preventing hazardous leaks in automotive parts to ensuring the sterility and integrity of pharmaceutical packaging, the implications of robust leak testing methods resonate across all touchpoints of production and usage.

Through the strategic use of advanced technology and equipment, industries are now better equipped to refine their leak detection capabilities, making them more capable of addressing the increasing complexity and requirements of modern products and materials. This careful balancing act between technological advancements and practical application defines the dynamic landscape of leak testing solutions today.

Understanding leak testing solutions

Leak testing plays a critical role in ensuring the integrity and performance of products that must remain sealed to function correctly. This section explores both basic and advanced techniques, providing a well-rounded view of available leak testing solutions.

Basic techniques in leak testing

Starting with basic methods, visual inspection is the most straightforward approach to checking the integrity of a product. It involves manually examining the exterior of a product to identify any noticeable defects such as cracks or misalignments that could lead to leaks. The simplicity of this method makes it universally applicable, but it also has its limitations. Visual inspections rely heavily on the observer’s acuity and can easily miss microscopic defects that could become problematic.

Another foundational method is bubble or submersion testing. This technique involves submerging a pressurized product in water or covering it with a soapy solution to watch for air bubbles, which indicate the presence of a leak. Though this method is simple and effective for locating the leak site, it does not quantify the size or rate of the leak, which limits its application in scenarios where precise measurements are crucial.

Advanced leak detection technologies

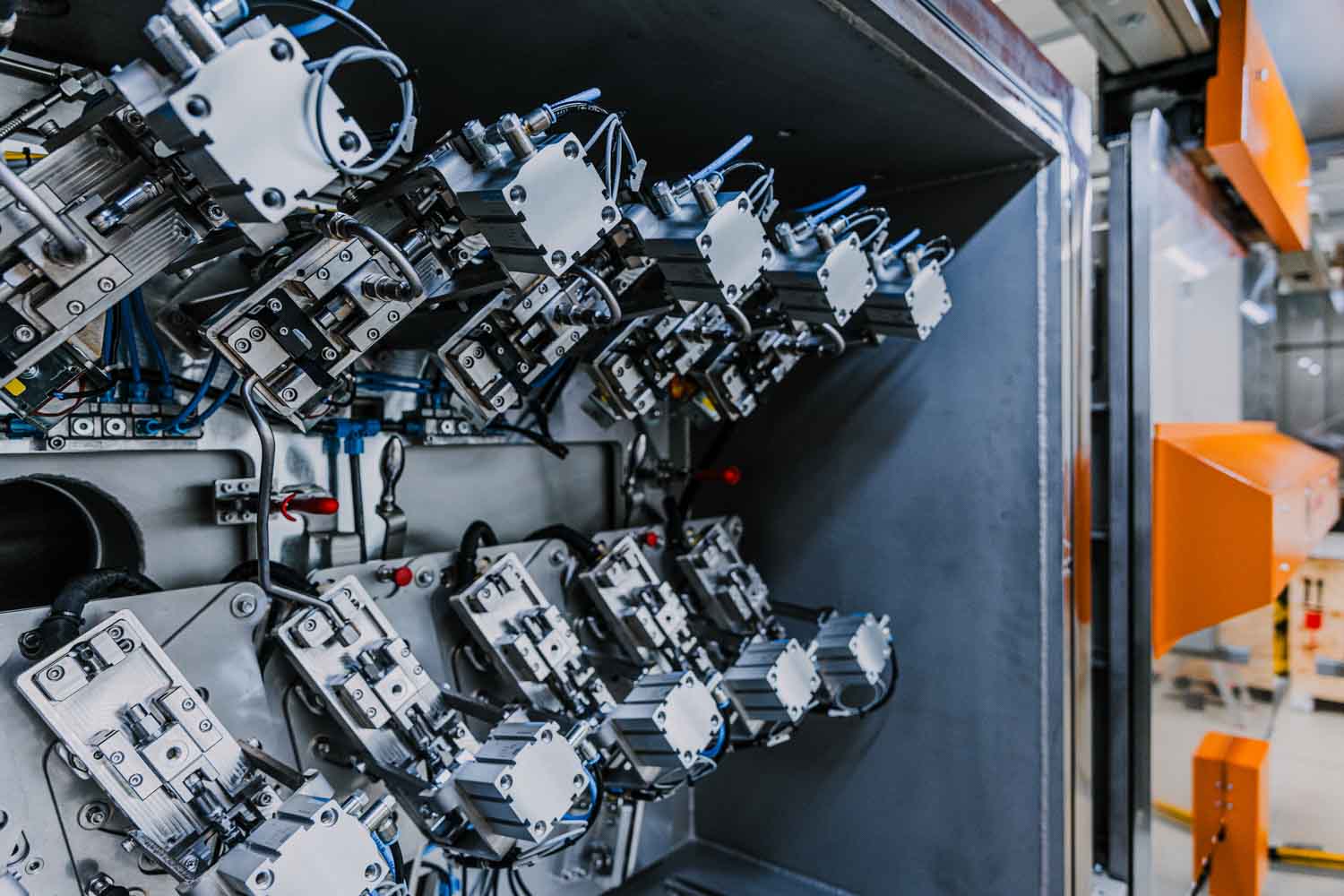

Moving to more sophisticated systems, hard vacuum leak detection presents a significant advancement. In this method, the item under test is placed inside a sealed chamber from which air is evacuated to create a vacuum. Introducing a traceable gas like helium into the product allows for the detection of even the smallest leaks, as the gas escaping is measured by highly sensitive detectors. This technology offers superior sensitivity and quantification compared to basic methods, making it suitable for high-stakes applications like those in aerospace and semiconductor manufacturing.

Helium techniques are varied and highly valuable in scenarios where detecting extremely small leaks is critical. Helium accumulation uses a closed chamber where helium is introduced to the test part. Any leakage leads to helium accumulation, detectable by precise instruments. Helium sniff involves charging the part with helium and then using a "sniffer" to detect the presence of helium outside the part, pinpointing the leak's location. Helium spray leak detection enhances this by applying helium to the exterior of a vacuum-sealed part to detect inward leaks. The sniffing method can be used to find the location of the leak, while the spraying method gives a precise result.

Pressure decay and vacuum decay methods measure the change in pressure over time either by introducing pressure into a system or by creating a vacuum. These methods have broad applications due to their adaptability to test various products, from small components to large assemblies. They are mostly used as a pre-test process before performing the helium leak test to avoid helium contamination in the machines due to gross leak (too big leak) but can be used as a stand-alone solution if their accuracy is enough.

Finally, ultrasonic leak detection uses the distinct sounds produced by gases as they escape from leaks to locate and measure leaks. This method is particularly useful for detecting larger leaks and can be applied in noisy environments where other detection methods might fail. Ultrasonic detectors translate high-frequency sounds produced by escaping gases, which humans cannot hear, into audible noises, allowing operators to detect and locate leaks easily.

Each of these methods brings distinct benefits and suits different applications, reflecting the complexity and variety of challenges faced when ensuring product integrity through leak testing. As we continue to push the boundaries of product performance and safety standards, understanding and choosing the right leak testing solution becomes not just necessary but a strategic advantage in production and quality assurance.

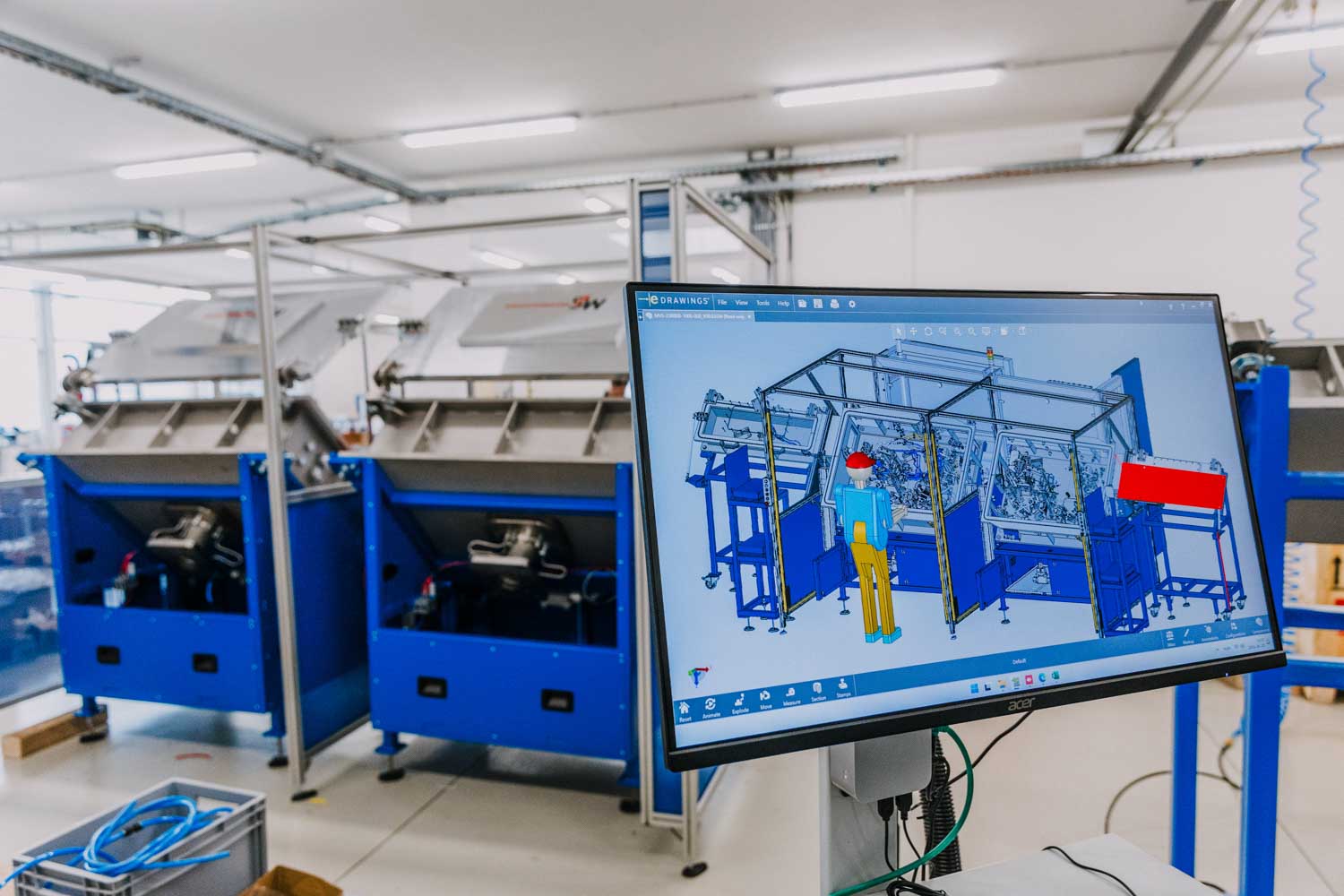

MVS Technologies is at the forefront of providing innovative leak testing solutions tailored to meet the rigorous demands of modern industries. Our array of technology includes highly accurate systems designed to ensure maximum quality control and safety. By leveraging advanced detection methods, MVS Technologies helps companies enhance product reliability. These solutions are crucial for sectors requiring precise standards, such as automotive, aerospace, and healthcare. As an industry leader, MVS Technologies remains committed to evolving its technology to address the dynamic challenges of leak detection.

Related posts

-

2024-06-09Helium leak detection system

2024-06-09Helium leak detection system -

2024-06-08The most common helium leak detection methods

2024-06-08The most common helium leak detection methods