Helium leak detection system: safeguarding integrity and safety

In today's industries, the helium leak detection system plays a crucial role in ensuring safety and reliability. While it may not always be in the spotlight, it serves as a vital guardian for various operations, from ocean depths to outer space. Let's explore helium leak testing, its significance in different sectors, and how it shapes industrial safety.

In industries and sciences, achieving perfection often faces the challenge of leaks. Even tiny breaches in a containing device can cause serious issues in functionality, safety, and efficiency. Helium leak testing, using one of the simplest elements in the universe, helps to uncover even the most elusive faults.

Helium leak testing is a sophisticated yet straightforward method to find small leaks in systems requiring high gas containment levels. This technique, using helium—a small gas molecule—detects leaks with exceptional sensitivity. By filling the test subject with helium and using special equipment, engineers can validate any leaks.

Why is helium used to filter leaks, and in which sectors is it particularly important? Read on for answers to these questions!

What is helium leak testing?

In industries like aerospace and medical devices, maintaining top-notch quality and safety standards is paramount. Helium leak testing stands out as a reliable and precise method for achieving this. But what exactly is helium leak testing, and why is it highly regarded across critical sectors?

Picture a system, like a complex network of parts crucial for aircraft safety or maintaining sterility in medical equipment. Ensuring this system is leak-free is not just important—it's essential for safety and function. Helium leak testing steps in here. It's a sophisticated, non-destructive method for locating leaks within a system. By using helium, known for its small size and non-reactivity, this method can pinpoint leaks with remarkable sensitivity and precision, guaranteeing system integrity and safety.

Helium leak testing combines physics and engineering seamlessly. The process begins by placing the product in a holder/adapter inside a vacuum chamber, where it can be adapted manually or automatically which ensures a leak-tight connection. After that the chamber and the product can be evacuated.) Why a vacuum? It sets the stage for the next crucial step—introducing helium into the product. Helium’s tiny molecules can escape even through the smallest leaks that other methods might miss. Once helium is introduced, a special detector finds any escaped helium, precisely identifying a leak. This method's elegance lies in its ability to detect tiny leaks with incredible accuracy—a must in high-stakes applications where even a slight leak could lead to disaster.

Helium's remarkable role in leak detection

Helium stands out in the world of leak detection for its exceptional abilities. Unlike other gases, it excels in finding even the smallest leaks.

- Sensitivity and precision

Helium's tiny size allows it to detect leaks with unmatched accuracy. It's like having a powerful magnet that instantly locates a needle in a haystack. - Safe and inert

Helium doesn't react with other substances, ensuring it doesn't harm materials or the operating personnel during testing. - Safety: non-flammable

Helium's non-flammable nature ensures safe testing without the risk of fire, especially in sensitive environments. - Versatile applications

Helium is used across various industries, from aerospace and automotive to medical device production, adapting effortlessly to different environments. - Swift detection

Helium quickly identifies leaks, crucial in industries where time is critical for decision-making.

Helium's exceptional properties make it an essential tool in leak detection, ensuring safety and efficiency across industries. Its quick and accurate detection capabilities make it invaluable for maintaining product and infrastructure integrity.

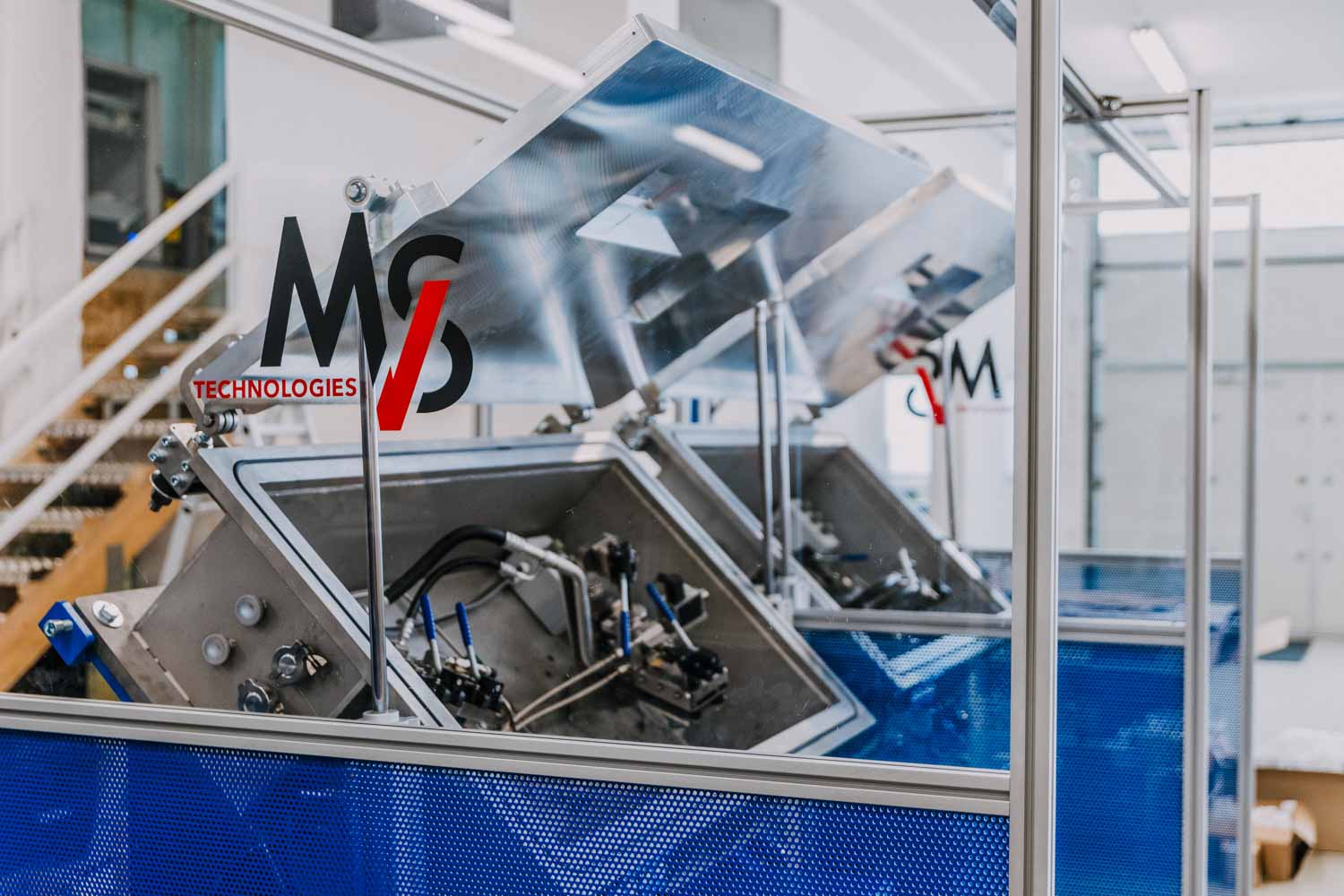

Helium leak detection system from MVS Technologies

MVS Technologies' helium leak detection systems are revolutionizing safety and efficiency in various industries. They handle test gases at pressures over 380 bar and can be customized extensively, from structural components to software. The systems include features like fixture identification, product presence sensors, and automatic barcode reading.

A key feature is the integration of advanced elements to boost efficiency and sensitivity. Vacuum chambers isolate helium pollution, enhancing detection sensitivity for smaller leaks. With precision testing capabilities detecting leaks as small as 1×10^-8 mbar*l/s, these systems cater to various products like fuel tubes, climate -tubes, -valves, and compressors.

MVS Technologies' commitment to innovation and sustainability is evident in its systems, surpassing industry standards with automatic test cycles, certified tools, and adaptable testing environments. Our efforts redefine industrial safety and integrity assurance.

Related posts

-

2025-10-08Helium leak detection: The gold standard in precision testing

2025-10-08Helium leak detection: The gold standard in precision testing -

2024-06-10Leak testing solutions

2024-06-10Leak testing solutions