Systems

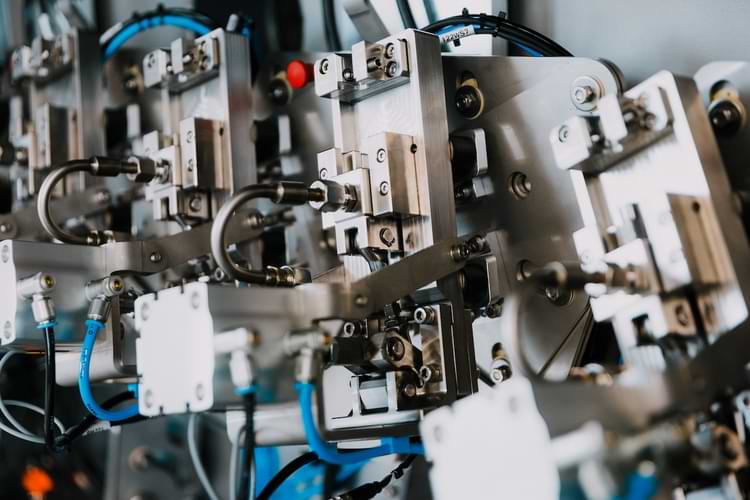

Throughout the years we have gathered a wide range of experience with different, mostly Tier1 automotive suppliers and OEMs. Some of our machines operating on the field are able to perform tests with helium test-gas at a pressure of 380 bar. Next to standard systems, we offer custom-made solutions, which enables us to satisfy the most complex customer requirements.

Some information regarding our systems features:

- Semi- and fully automated solutions

- Exchangeable adaptation with or without identification of the fixture

- Product identification, with presence sensors and manual or automatic barcode reading

- Adaptation on the same position as the product will be adapted in the car. With O-ring sealing or with self-pressed rubber sealing – for less sealing exchange

- All our machines have a (data storage capability) traceability system, but we can integrate our system to the customer’s MES

Services

There are many occasions where our customers rely on our services. Our experienced, well-trained team is always here to support you whatever the reason is. Although there might be more of them, but we have categorized our services in groups for a better overview. We are offering you: Support, Retrofit, Training, Maintenance and a special support for product development & pre-series testing.

What we do

Prototype design development

We help you to develop the best design for your customer / application and provide testing solutions for your proto components.

Design

Our first priority is to find the best solution for your application.You share your requirements with us and we design a system that fits to your needs at most.

It is a long way to meet all the expectation and during this time period we provide you all the support to achieve this mission.

Manufacturing & Assembling

After the design freeze we can start the manufacturing and assembling as well as the programming processes until the system is ready for the pre-acceptance test at our facility. Customers are always welcome to monitor our operation during the whole time.

Installation & Support

Before closing the project our team installs the equipment at your facility and prepares it for the production.After a successful final acceptance test we make sure that the responsible persons receive all the necessary informations/trainings from us to ensure a safe and reliable operation.

MVS designs and manufactures custom-made, high-end vacuum systems for a wide range of applications.

With over 30 years of experience, our team provides solutions for Industrial, R&D systems and a professional before- and after-sales support to ensure a safe operation.

Industry Expertise

Value creation and continuous development through strategic, long-term cooperation.

- Industry-specific experience, willingness to invest

- Decades of experience in helium-based testing technology

- Knowledge of alternative testing technologies

- Innovation and product development

- Use of cutting-edge technologies

- Trained engineering and manufacturing team

- International project references

- Partner-focused pricing and project management routine

- Strong knowledge of international value chains and players

Flexibility

Effective implementation of the problem-based solution mix in each of our projects.

- Effective implementation of the problem-based solution mix in each of our projects.

- Engineering support to solve specific problems

- Logistics and assembly support

- Fast and accurate quotations based on unique needs

Partner-focused business model

Value creation and continuous development through strategic, long-term cooperation.

- Information sharing and effective communication

- Solving engineering problems according to the partner's needs

- Effective, solution-oriented engineering advice and management

- Expert engineering assistance for naive clients.

- Long-term commitment

- Long-term support for existing systems

- Long-term service support

Automotive

Leak testing is an essential part of the automotive manufacturing process to ensure vehicle safety and reliability.

Aviation

Leak testing is an essential part of the aviation manufacturing process to ensure aircraft safety and durability.

Consumer goods

Leak testing and leak detection are essential for the safety and quality of consumer products

Packaging

In the packaging industry, leak testing is necessary to prevent product loss, damage, and contamination.

Medical devices

Leak and function testing of disposable medical devices for maintaining safety standards.

Valves and fittings

Leak testing and leak detection procedures must be performed to maintain the integrity and effectiveness of valves, fittings, and faucets.

Fast-growing international presence

- Hungary

- Germany

- Czech Republic

- Poland

- Belgium

- Portugal

- Spain

- Mexico

- Republic of South Africa

- Turkey