In industries where safety, product integrity, and uptime matter most, a leak detection system plays a critical role. Whether you're testing automotive parts, gas valves, or medical devices, it's not just the machine itself that ensures success, but the full lifecycle support behind it. Using helium-based testing, these systems must be exceptionally reliable. That reliability comes from more than just good design. Many production failures are not due to a faulty product, but because the leak detector wasn't tested, maintained, or appropriately calibrated over time. That's why lifecycle thinking (covering everything from prototyping to retrofitting) is essential. When every second of downtime costs money, long-term support becomes a strategic asset.

Customisation starts at design: built for your product

Every leak detection system from MVS Technologies begins with you, the customer. Machines must often perform under unique conditions: irregular part geometries, special sealing needs, or limited installation space. At this phase, our engineers work closely with your team to tailor the right solution.

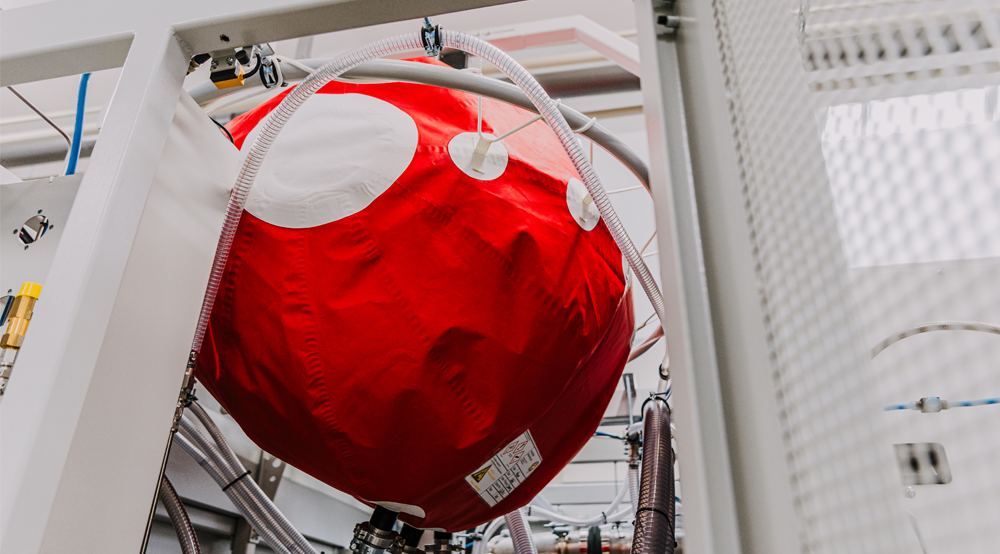

We don't just design: we solve problems. Whether you need the system to test at 380 bar using helium as the test gas or require a chamber custom-built for oddly shaped products, it's all part of the plan. Each system is designed with future expansion in mind, making later upgrades smooth and cost-effective.

Precision in production: where machines meet purpose

Once the design is finalised, the real work begins. Manufacturing and assembling your leak detection system requires high standards. MVS builds systems ready for semi- or fully automated operations, and all accessories and software are aligned with your unique setup.

Key features include:

- Barcode or sensor-based product identification

- Adaptation systems to securely fit your product

- Optional integration with your production's MES software

Each leak detector is built for accuracy and consistency, so you're never second-guessing your results.

Training and setup: A leak testing system is only as good as its operators

It's easy to underestimate the importance of comprehensive training when launching a new machine. But long-term performance begins with a strong start. That's why MVS offers installation support and user training as part of every package.

Once installed, we don't disappear. We assist during the final acceptance test and train your staff to handle day-to-day leak testing procedures, check for gas loss, and safely operate the system. This early phase ensures security in your operations and sets the stage for years of uninterrupted performance.

Scheduled maintenance and support: your safety net

Even the best machine needs ongoing care. Our lifecycle services include regular maintenance, expert support, and precise calibrations. These steps are essential to make sure your leak detector keeps operating at maximum sensitivity and doesn't falsely pass or fail a product.

Why invest in routine maintenance?

- It significantly extends machine lifespan

- It minimises unexpected downtime

- It maintains consistent helium gas usage and test accuracy

With decades of experience, our support team can quickly identify and resolve issues, offering both remote and on-site services.

System upgrades and retrofitting: adapting for what's next

Technology moves fast. If your existing leak detection system was built years ago, that doesn't mean it's obsolete. MVS offers retrofit services that upgrade older machines with new hardware, smarter software, or enhanced accessories.

This means:

- Better helium gas control

- Faster test cycles

- Integration with modern production systems

Instead of investing in a brand-new detector, you can bring your current system up to speed, saving both time and money.

Industry-wide reliability: one leak testing solution, many applications

A great leak detection system should work across industries, and MVS ensures it can.

We serve sectors like:

- Automotive: Ensuring the safety of fuel lines, batteries, and airbags, and much more

- Medical: Verifying the integrity of disposable devices

- Consumer Goods: Avoiding leaks in packaging and home-product valves (heat pumps, cooling compressors/cooling systems)

- Aerospace: Where security and durability requirements are strict

No matter the product, helium testing is often the preferred choice due to its precision and reliability in identifying even microscopic leaks.

Long-term partnership: more than a service, a commitment

Supporting a leak detection system isn't a one-time job. It's a long-term responsibility. We believe in building relationships with manufacturers that go beyond shipping a machine. Our lifecycle support ensures continuous performance, compliance, and adaptability.

When you choose MVS Technologies, you gain:

- A support team with 30+ years of experience

- Engineering consultants who understand your industry

- Lifecycle services designed to secure your production and extend equipment life

We're ready to grow with you - not just for today's products, but tomorrow's as well.

The demand for leak detection systems that are both precise and durable has never been higher. But owning the best-in-class machine isn't enough. Without maintenance, training, and proactive upgrades, the return on your investment can shrink over time.

Lifecycle support maximises that return, extending the value of your leak detector and accessories. At MVS, we believe in full-spectrum service: tailored design, setup, testing, and ongoing support; all to ensure you never have to worry about leaks, downtime, or wasted helium gas again.

For more details, visit MVS Technologies!