Helium serves as the benchmark for precision leak detection in critical industries, where even the smallest oversight can lead to catastrophic failure. Its unique physical and chemical properties make it exceptionally suited for identifying microscopic leaks in sealed systems. Being an inert gas, helium does not react with other materials, ensuring it does not interfere with test components. Its non-toxic nature makes it safe for operators and environmentally sound for industrial use. Thanks to its small atomic size and low viscosity, helium can penetrate the tiniest openings and flow effortlessly through even the smallest leak paths. Additionally, its non-flammable property removes fire risks during testing, making helium a safe choice for critical applications.

These properties enable helium-based testing to achieve sensitivity levels that are significantly higher than those of other methods. Industries such as automotive manufacturing and aerospace engineering rely on this precision to ensure component integrity, safety compliance, and operational reliability.

The importance of helium leak detection becomes clear when considering the consequences of undetected leaks: catastrophic system failures in medical devices, compromised safety in automotive fuel systems, or critical malfunctions in aerospace applications. These situations highlight why helium remains essential, despite new challenges.

The industry faces a difficult balance between maintaining technical excellence and addressing sustainability concerns. Rising helium costs, global scarcity issues, and environmental considerations now influence how manufacturers approach leak detection strategies without sacrificing the accuracy that helium uniquely offers.

The unmatched precision of helium leak detection

Helium's atomic diameter makes it the smallest noble gas molecule, allowing it to penetrate through microscopic pathways that larger molecules cannot traverse. This fundamental property allows helium leak test systems to identify leaks, detecting defects that would remain invisible to conventional testing methods.

The sensitivity advantage becomes apparent when comparing helium mass spectrometry to pressure decay testing. Modern leak detection technology, utilising helium, achieves sensitivity levels up to one million times greater than traditional pressure-based methods.

Vacuum leak detection applications demonstrate helium's versatility under diverse operating conditions:

- Vacuum conditions: Electronic component housings, semiconductor packaging, and research equipment requiring ultra-high vacuum integrity

- Pressure applications: Automotive fuel systems, medical device seals, and pressure vessel testing, where components operate under positive pressure

Safety considerations distinguish helium from alternative tracer gases. Its non-flammable nature eliminates explosion risks in industrial environments, while its non-toxic properties protect operators during extended testing procedures. These characteristics enable deployment of helium leak test systems in confined spaces and sensitive manufacturing areas where other gases would pose unacceptable hazards.

Helium conservation strategies become essential when leveraging these precision capabilities, as they balance detection accuracy with resource management requirements.

Challenges associated with helium use in leak detection

Helium Shortages

Helium shortages pose a significant challenge for industries that rely on precision leak detection. As a finite resource primarily extracted as a byproduct of natural gas processing, helium availability depends heavily on global energy markets and geological factors. The United States historically dominated helium production through its Federal Helium Reserve; however, the depletion of this strategic stockpile has shifted supply dynamics to Qatar, Algeria, and Russia, creating geopolitical vulnerabilities in the supply chain.

Escalating procurement costs

The economic impact is evident in escalating procurement costs that strain operational budgets across various manufacturing sectors. Helium cost reduction strategies become essential as prices fluctuate dramatically, sometimes increasing by as much as 300% within a single year. These price volatilities force manufacturers to reconsider their quality control protocols, potentially compromising testing frequency or seeking less sensitive alternatives that may not meet stringent safety requirements.

Environmental concerns

Environmental considerations compound these challenges as traditional helium testing releases the gas directly into the atmosphere after each test cycle. Unlike other industrial gases, helium cannot be economically recaptured from the atmosphere, representing a permanent loss of this precious resource. Each cubic metre of helium released during testing procedures contributes to global depletion whilst generating no recoverable value.

Balancing quality and costs

These converging pressures influence critical manufacturing decisions. Companies must balance maintaining rigorous quality standards against rising operational costs, leading some to reduce testing frequency or explore hybrid approaches that combine helium testing with alternative methods for preliminary screening.

MVS Technologies' approach to sustainable helium usage

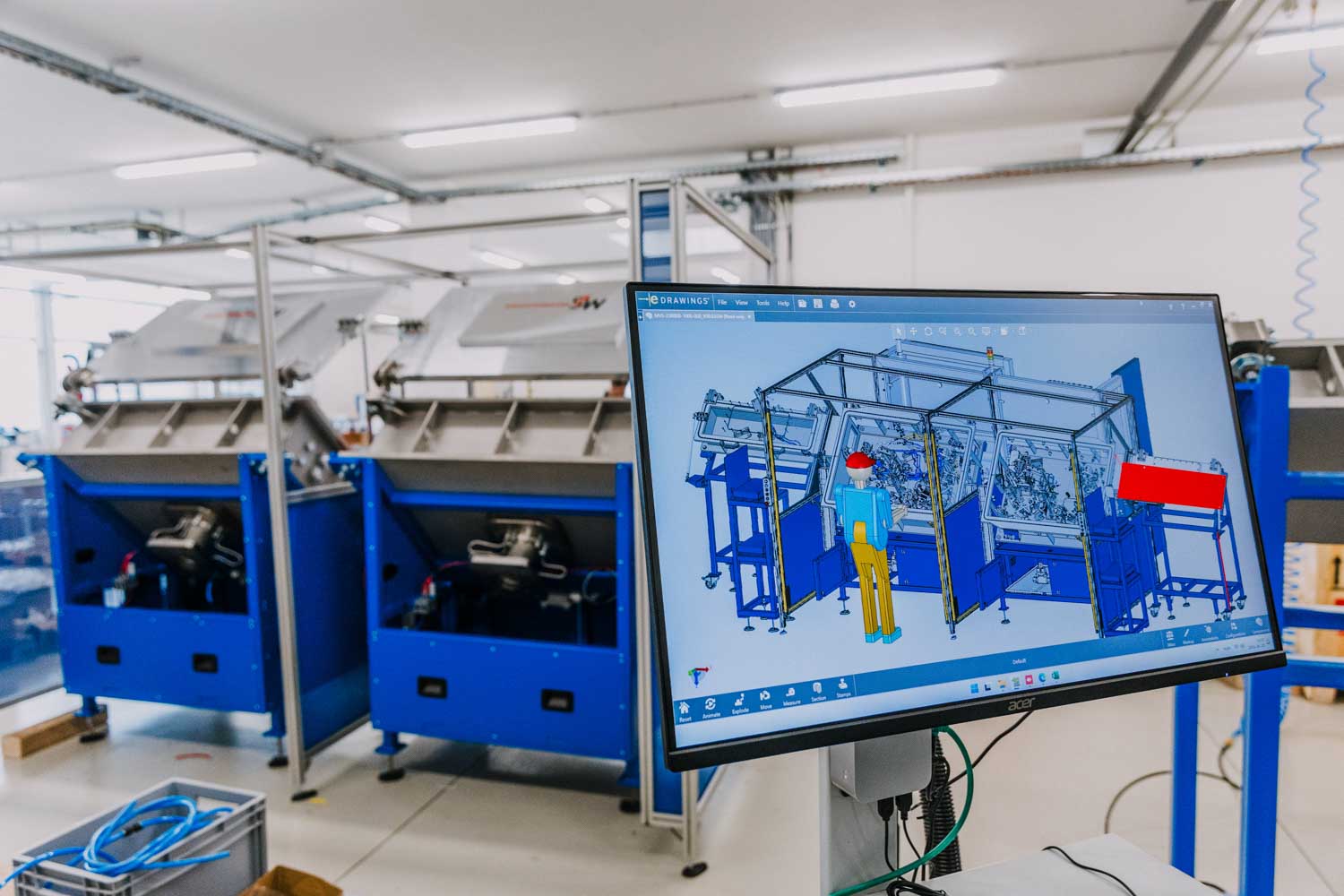

MVS Technologies has redefined helium usage in leak detection by developing an advanced helium recovery system, which transitions the process from a single-use model to a sustainable, closed-loop operation. With recovery efficiencies reaching up to 95%, our Helium Recovery Units (HRUs) dramatically reduce helium consumption and operational costs, while also mitigating environmental impact. Designed for seamless integration into existing production lines, these systems enable helium to circulate continuously, rather than being discharged into the atmosphere. At the heart of this innovation are real-time monitoring systems that track consumption and recovery. These automated purification processes ensure consistent gas quality and smart process controls that optimise test sensitivity with minimal helium usage. Thanks to a modular architecture, our HRUs can be tailored to various production environments, making sustainable helium management both practical and scalable.

Industry applications highlighting the importance of helium leak detection

1. Automotive industry: Ensuring safety and performance

Leak detection in the automotive industry highlights the critical role of helium in ensuring vehicle safety and performance. Fuel system components undergo rigorous helium testing to prevent dangerous leaks that could lead to fires or emissions violations. Air conditioning units require precise leak detection to maintain refrigerant integrity and comply with environmental regulations. The automotive sector's zero-tolerance approach to safety makes helium's exceptional sensitivity indispensable for detecting microscopic breaches that pressure-based methods might miss.

2. Medical devices: Safeguarding patient safety

Leak testing for medical devices requires the highest precision standards, as patient safety depends on component integrity. Implantable devices, surgical instruments, and diagnostic equipment undergo stringent helium leak detection to ensure sterile barriers remain intact. The non-toxic nature of helium eliminates contamination risks during testing, whilst its small atomic size reveals defects that could compromise device functionality or patient wellbeing.

3. Energy storage: Maintaining reliability

Energy storage leak detection has become increasingly vital as battery technologies advance. Lithium-ion battery casings require hermetic sealing to prevent electrolyte leakage and maintain thermal stability. Helium testing identifies potential failure points that could lead to thermal runaway or reduced battery life, ensuring both safety and performance reliability in electric vehicles and energy storage systems.

4. Aerospace: Verifying integrity under pressure

Aerospace leak testing operates under the most demanding conditions, where component failure can have catastrophic consequences. Spacecraft systems, satellite components, and aircraft pressurisation systems undergo extensive vacuum leak testing using helium to simulate extreme operational environments and verify absolute integrity under pressure differentials.

Enhancing efficiency through advanced engineering solutions

Helium efficiency in manufacturing requires precise systems that eliminate measurement uncertainties while maximising resource utilisation. MVS Technologies' vacuum engineering solutions use decades of experience in building strong test environments. Custom-made fixtures maintain constant pressure differences across various component shapes, ranging from complex medical device casings to large automotive parts. Each system undergoes rigorous validation processes to confirm that background leak rates are significantly lower than the detection limits.

Helium's unmatched accuracy in leak detection technology ensures its continued dominance across critical industries, despite growing challenges from resource scarcity and rising costs. The future of industrial leak testing lies not in abandoning this gold standard, but in finding new ways to use it through advanced recovery systems and intelligent process design.

MVS Technologies' pioneering approach to sustainable helium use demonstrates that environmental responsibility and technical excellence can coexist. With recovery efficiencies reaching 95% and smart integration capabilities, these innovations extend the lifespan of this precious resource while maintaining the stringent accuracy demands of modern manufacturing.

Contact us for tailor-made helium leak testing solutions!