Throughout the years we gathered a wide range of references at different, mostly Tier1 automotive suppliers and OEMs. Some of our machines operating actually on the field are able to perform tests with helium test-gas at a pressure of 380 bar. In case of any special requirements, we would be pleased to develop a new solution for it.

We are able to develop our machines to the requirements of our customers (from the structure, through the adaptation, to the controlling software and the visualization), but we can offer our standard systems with our standard control software and HMI as well.

A few of our machines in groups according to products

Leak detection systems

Our main profile is to design and manufacture helium leak detection systems. Most of our systems have one, or more vacuum chambers where the product(s) can be placed during the test. With the help of the vacuum chambers the helium pollution from the surroundings can be isolated and in this way the systems sensitive is becoming higher, identification of smaller leaks is easier and more stable.

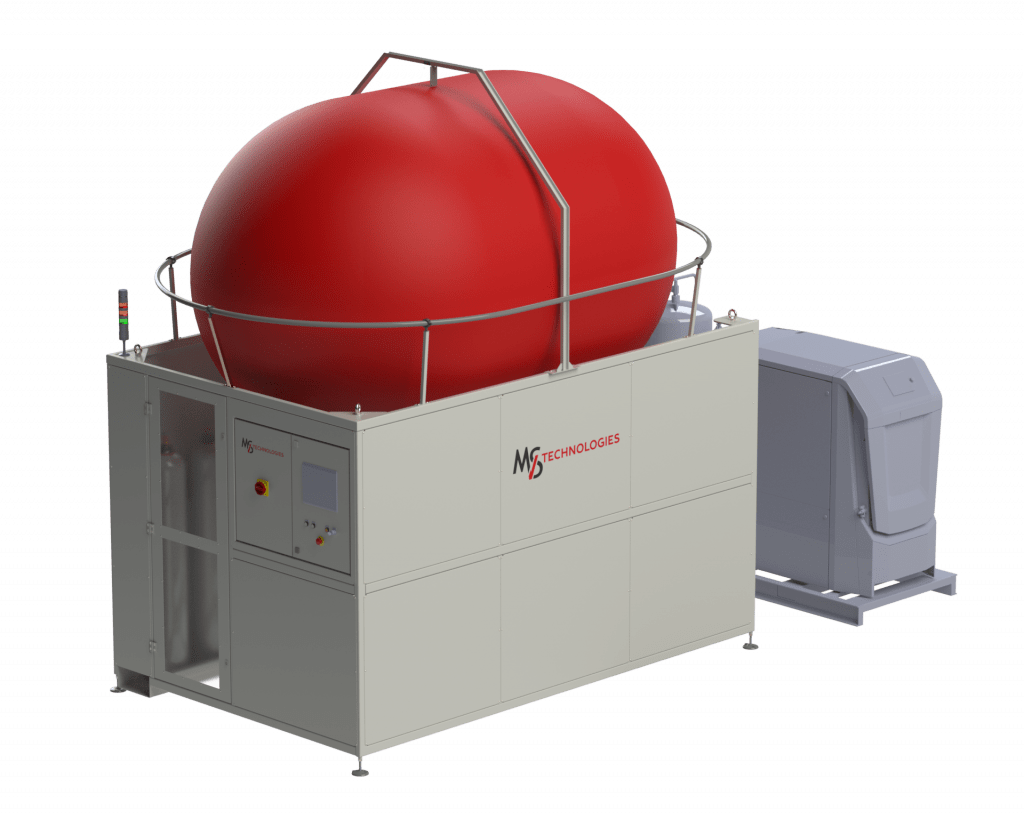

Helium Recovery Units (HRU)

When the test-gas is released from the product at the end of the cycle, the used Helium gas will be waisted and thrown out (usually outside the facility through a exhaust pipeline). Our helium recovery unit ensures the possibility to reuse the test gas for multiple times. Another huge advantage is that the helium bottle or bundle completely can be emptied before exchanging it. Without the HRU at least the same pressure as your testing pressure will have to remain in the bottle when it has to be exchanged. We have these units in different sizes, but the concept is very similar.

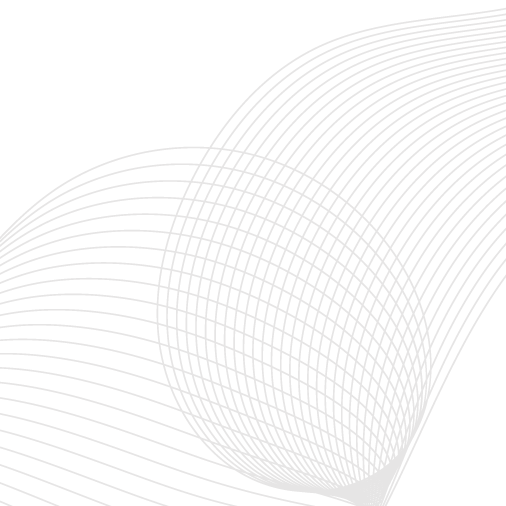

Fuel Tube Testers

- Semi-automatic test cycle according to specified recipes with manual adaptation of the product by the operator

- Exchangeable adapter plate specific for test piece

- Variable number (1 to 4) of test piece per chamber

- Automatic recognition and recipe allocation is possible

- Thanks to certified calibration tools, quality is assured and provable.

- Chamber size optimized to customer needs

- Optional accessories such as 2D scanner, printer, preferred PLC, etc.

Test gas pressure

32 – 380 bar

Throughput of the system

40-60 s

Handling

By operator

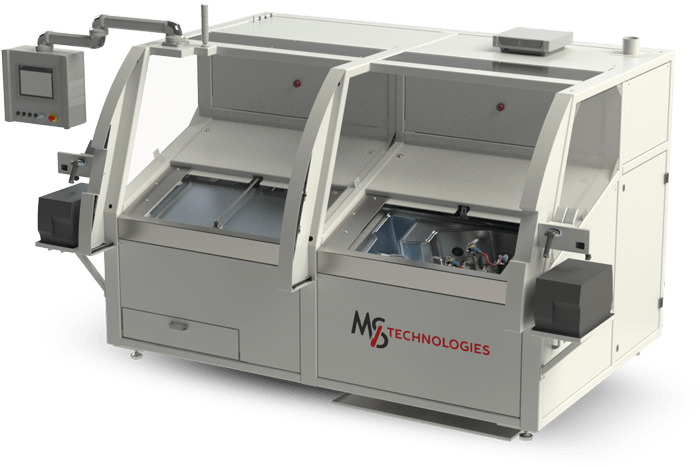

Ball valve-, Valve module- and Needle valve Testers

- Semi- and fully automatic test cycle according to specified recipes with/without operator influence

- Exchangeable adaptation/fixture specific to test piece

- Automatic product recognition and recipe allocation is possible

- 1 test piece per test chamber

- Thanks to certified calibration tools, quality is assured and provable.

- Chamber size optimized to customer needs

- Optional accessories such as 2D scanner, printer, preferred PLC, etc.

Test gas pressure

100 mbar – 170 bar

Throughput of the system

18-130 s

Handling

By robot, or by manipulator and/or by operator

Additional features

LIN communication, Overall and single circle tests, etc.

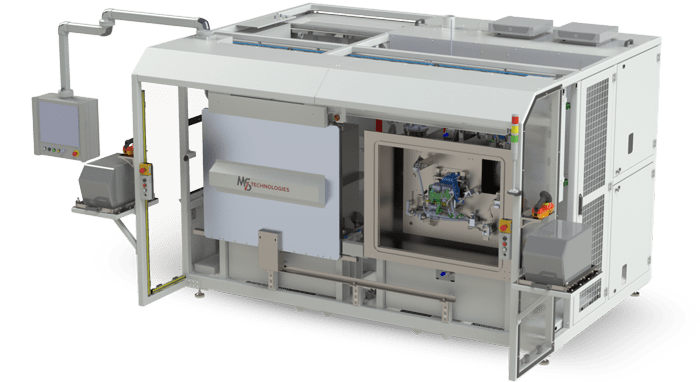

Fuel Tank Testers with integrated HRU

- Semi-automatic test cycle according to specified recipes with manual adaptation of the product by the operator

- Exchangeable product type specific adapter plates (if required)

- Automatic product type recognition through automatic barcode reading and recipe allocation is possible

- 1 test piece per test chamber

- Thanks to certified calibration tools, quality is assured and provable.

- Chamber size optimized to customer needs

- Optional accessories such as 2D scanner, printer, preferred PLC, etc.

Test gas pressure 100 – 500 mbar

Throughput of the system

65-120 s

Handling

By operator

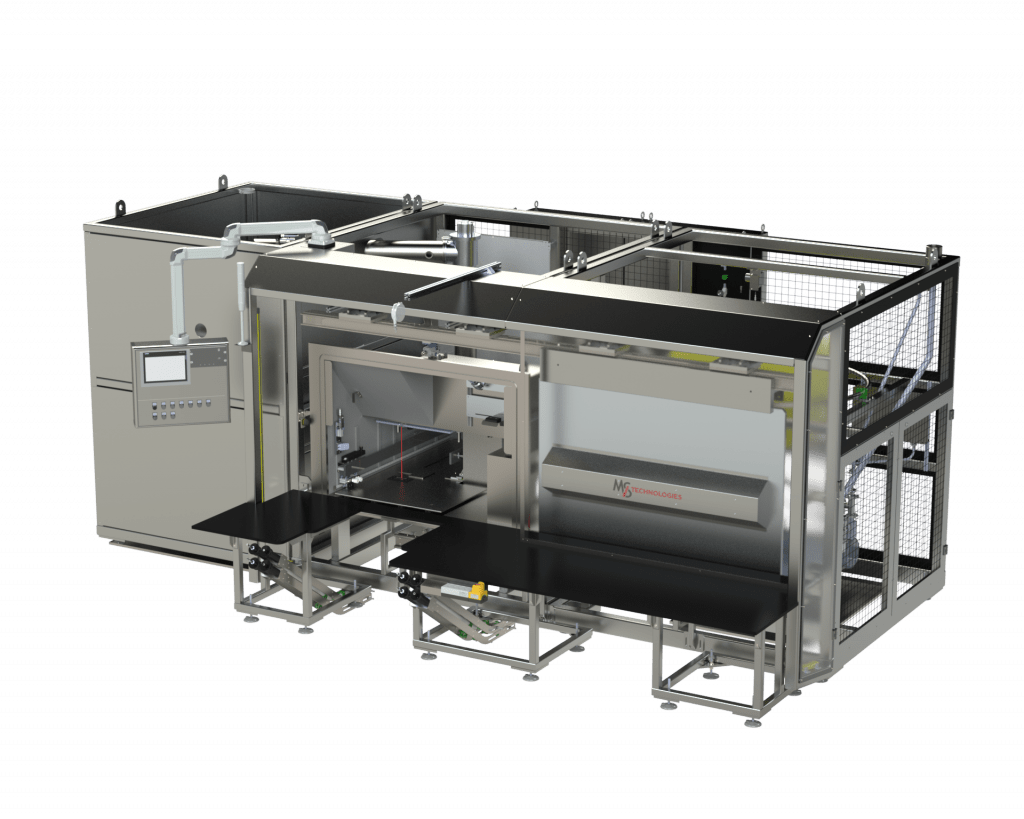

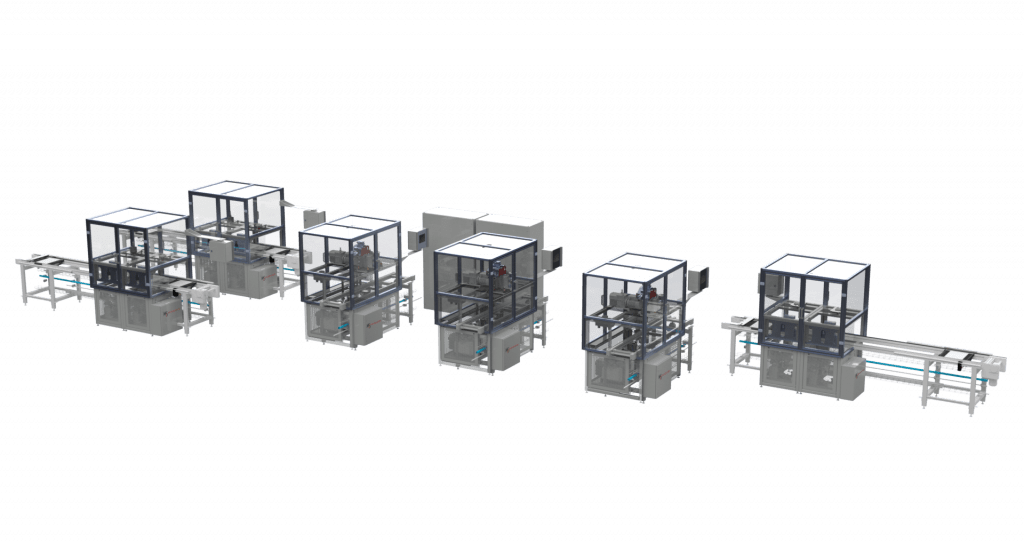

Compressor Tester Lines

- Fully automatic test cycle according to specified recipes without operator influence

- Automatic changeover with servo units

- Recipe downloads from the High-level PLC

- 1 test piece per test chamber

- Thanks to certified calibration tools, quality is assured and provable.

- Chamber size optimized to customer needs

- Optional accessories such as 2D scanner, printer, preferred PLC, etc.

Test gas pressure

17 bar

Throughput of the system

24 / 12 s

Handling

Automatic by conveyor

Helium Recovery Units (HRU)

- Ecofriendly, especially in view of environmental certifications according to ISO 14001.

- Short payback period. Payback time depending on the consumption and pressure requirements

- It can be a stand-alone or integrated system. A stand-alone system can supply multiple testers.

Operating pressure

1 – 400 bar

Balloon volume

2-10 m3 (or on request)

Efficiency

up to 95 %

Volume throughput

1-25 m3/h (or on request)

Helium concentration

10-95%